The critical role of cot surface in spinning efficiency

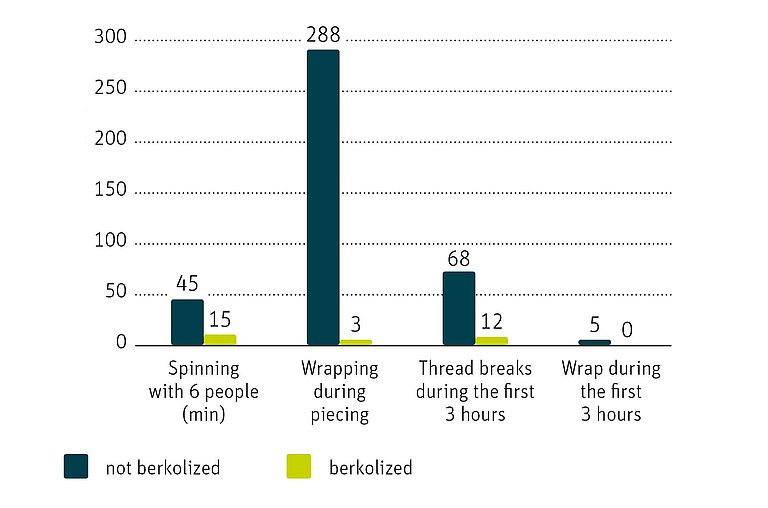

Berkolizing (UV treatment of rubber cot covers) is a fast, safe and reproducible surface treatment that improves fiber guidance, reduces lapping and thread breaks, and increases overall spinning productivity.

Why Cot Surface Matters

In ring spinning, cot covers may seem like a small component, but they play a decisive role in fiber control, yarn quality, and process stability.

The surface characteristics of cots directly influence fiber drafting, tension control, and the risk of lapping or breakage. Maintaining optimal cot conditions is essential for consistent, high-quality yarn production and maximizing machine efficiency.

Optimized Cots, Optimized Output

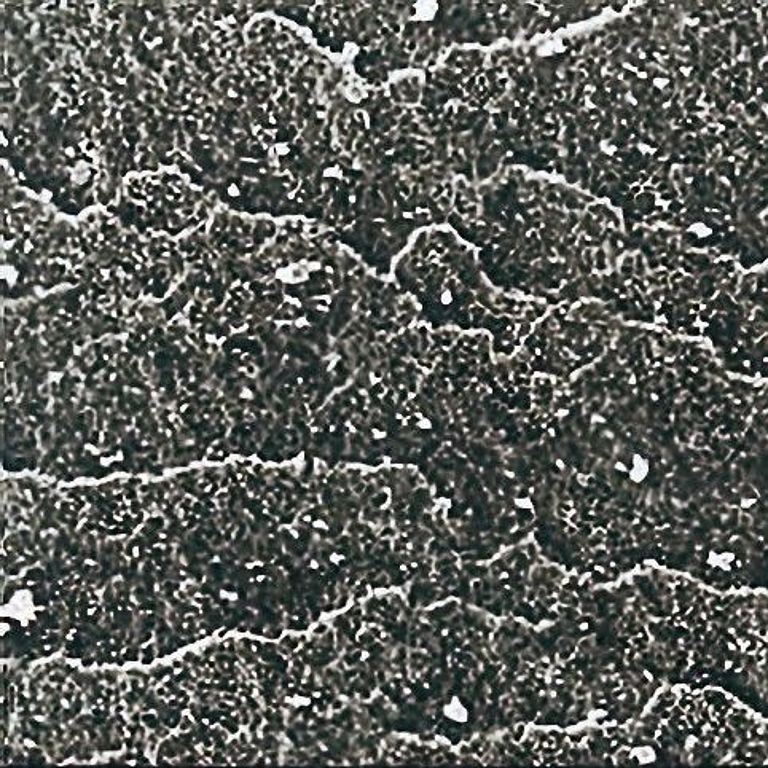

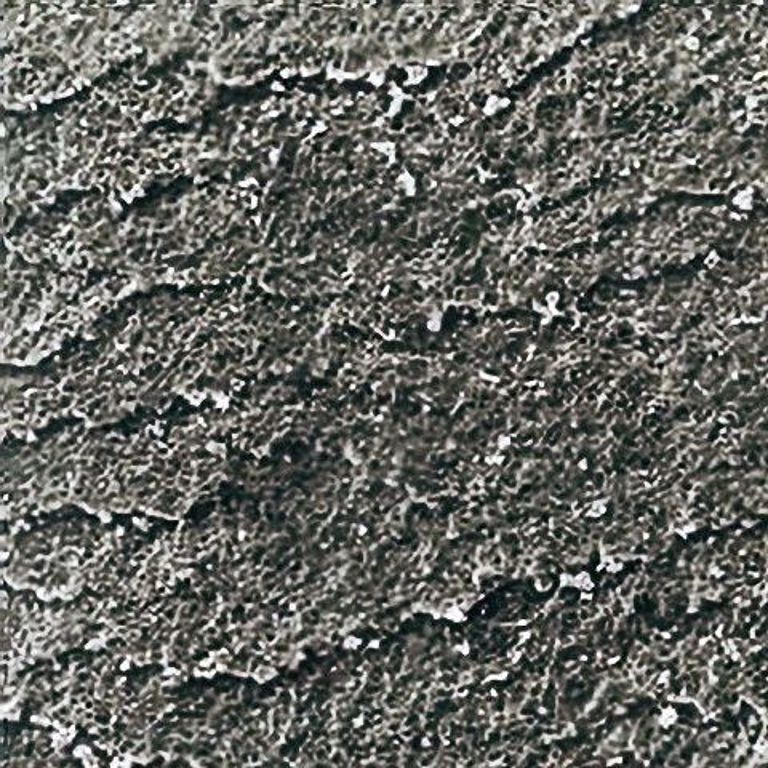

When grinding rubber cots, plasticizers are released to the surface, making it slightly tacky. Treating this freshly ground surface with UV light induces controlled modification of the rubber, causing minimal changes (detectable only under a scanning electron microscope) and producing a smoother finish. The cot itself remains unaffected, but its running properties — faster machine start-up, fewer yarn breaks, and more stable production — are significantly improved.

UV Precision Without Material Compromise

The process involves controlled exposure of the cot surface to UV radiation. Treatment times are optimized according to cot type, hardness, material composition, and desired yarn quality. For example, ring spinning cots typically require only 3–5 minutes in the latest automated Berkolizing machines.

Safe, green, and reproducible

Traditional anti-lapping methods, such as acids, solvents, or talc, come with safety risks, disposal challenges, and inconsistent results. Berkolizing eliminates these concerns. The UV process is non-toxic, dry, and can be fully automated, ensuring reliable outcomes without exposing operators to hazardous materials. With set exposure times and controlled intensity, mills can achieve identical, reproducible results every time.

FAQ

Will UV fix a poor quality cover or bad grind?

No — berkolizing optimizes an already good, finely ground cover. It cannot compensate for a low-quality rubber or a poor machining job.

Is berkolizing safe for operators?

Yes — unlike solvent/acid treatments it is non-chemical and can be fully enclosed and automated for operator safety.

How often to re-treat?

Best practice is to berkolize after grinding and as part of regular maintenance; exact intervals depend on grind schedule and mill process.

Berkolizing machines

Bräcker state-of-the-art Berkolizers make berkolizing simple, safe, and fully reproducible. Designed for modern spinning mills, they automates the UV treatment process and ensure every cot gets the perfect surface finish — every time.