As one of the key components in ring and compact spinning, Bräcker offers travelers in various shapes and finishes to fit any requirements.

Ring Travelers for Short-Staple Spinning

Decisive for a perfect quality of the spun yarn- High productivity

- Maximum production consistency

- Optimum running characteristics

- Universal applicability

Shapes

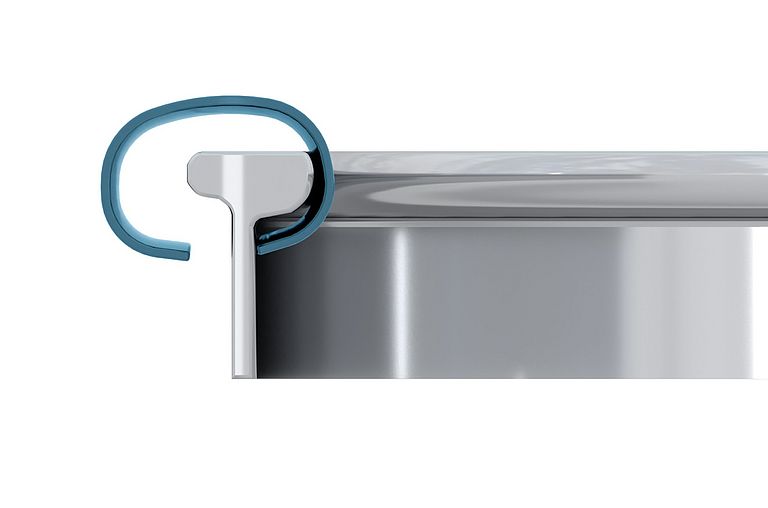

C-shaped travelers for T-flange applications

The contact area to the ring surface is punctiform. The traveler aligns itself optimally to the load during operation.

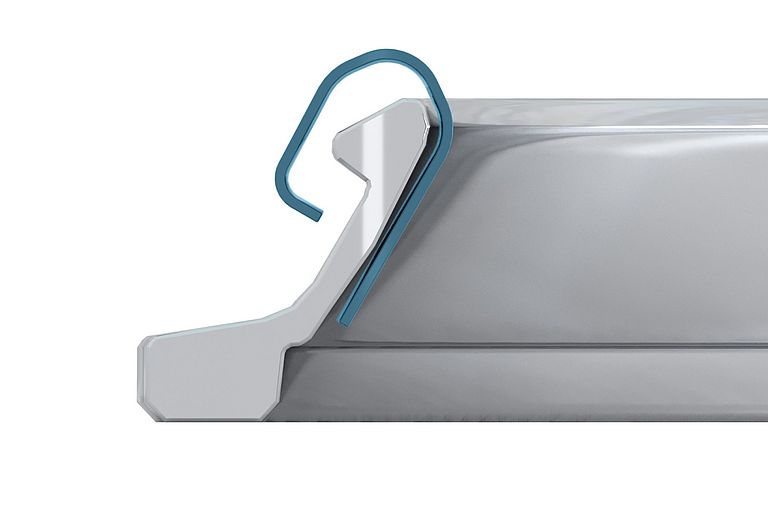

SFB travelers for ORBIT rings

There is a larger contact surface between the ring and the traveler and the traveler has a larger yarn passage. This results in higher heat dissipation and greater stability when the traveler is running.

FINISHES

SAPHIR

SAPHIR travelers have been exposed to a special diffusion process. The enrichment components are present on the surface and throughout the traveler body. This guarantees consistently good running conditions over the entire lifespan of the traveler.

Highlights:

- For all fiber types and yarn counts

- For both, regular operation and running-in

ONYX

The improved gliding characteristics make it possible to increase the spindle speed by up to +1 000 rpm and prolong the lifespan of the traveler by as much as +50%. Furthermore, the running-in period is considerably reduced.

Highlights:

- For cotton yarns, including compact

- For high spindle and traveler speeds

STARLET

STARLET travelers are finished with a fine and compact nickel layer. Low friction values in the yarn passage prevent fiber damage and ensure good gliding characteristics after the traveler is changed.

Highlights:

- For demanding environmental conditions

- For man-made fibers and blends

STARLETplus

Processing aggressive fibers can lead to cutting marks in the yarn path. The time it takes for such cutting marks to appear sets the benchmark for traveler quality.

Highlights:

- For viscose and cotton-viscose blends

- For polyester and dyed fibers

CARBO

A traveler designed to meet the requirements of spinning mills that work with man-made fibers.

Highlights:

- For man-made fibers, blends and core yarns

- Good gliding characteristics

PYRIT

The PYRIT treated traveler features unbeatable performance in terms of service life and speed. It can last up to three times longer than a regular traveler.

Highlights:

- For all fiber types

- No cutting-in in the yarn path

- Extended traveler replacement intervals

ZIRKON

The innovative ceramic coating gives the traveler a service life of over 1 000 hours.

Highlights:

- Lower machine downtime

- For highly automated spinning mills with long machines

- For installations with potential for high speeds

Downloads

Contact

Bräcker always wants to answer queries quickly and competently.